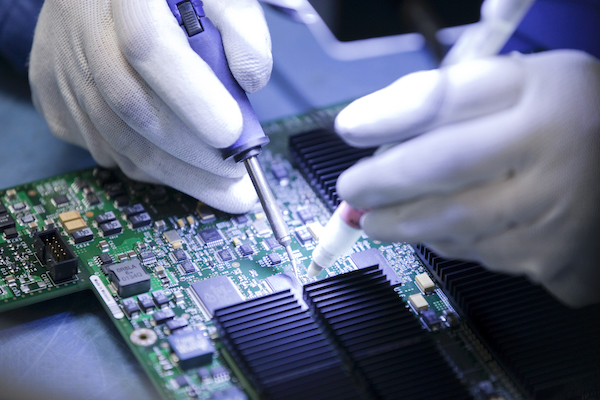

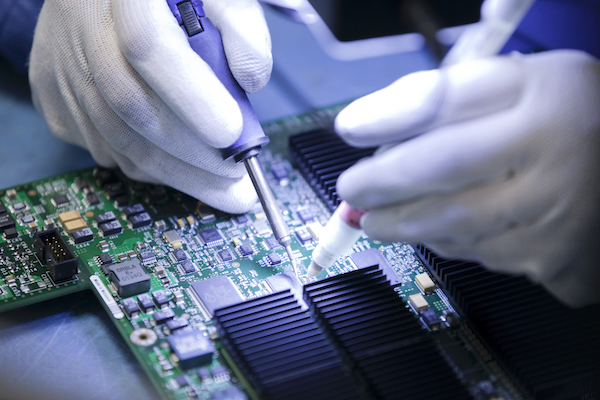

The COVID pandemic has made us more reliant than ever on digital connectivity and telecommunications. From handheld devices and screens, to servers, routers and wireless access points, millions of companies and families worldwide rely on electronic devices for their connectivity and communications needs.

The COVID pandemic has made us more reliant than ever on digital connectivity and telecommunications. From handheld devices and screens, to servers, routers and wireless access points, millions of companies and families worldwide rely on electronic devices for their connectivity and communications needs.

What if the materials required to make these products came to be in short supply?

This isn’t a hypothetical question. The range of recent supply disruptions has made it clear that the world’s supply lines can be stopped at a moment’s notice, and we need to be prepared. The global shortage in semiconductors has been wreaking havoc on worldwide supply chains, and cobalt shortages are driving price hikes and bottlenecks for smart phone and electric vehicle battery manufacturing. Even mundane commodities such as toilet paper and wipes have suffered severe supply shocks in the last year.

In light of increasing global supply chain uncertainty, companies are shifting their attention toward a circular economy. The premise is simple: by extending the lifetime of products through reuse, repair and remanufacturing — and recovering important raw materials from products at the end of their useful lives — we minimize the need to extract more raw materials for new products. Cisco believes that creating a circular economy is as disruptive — in a good way — as the development of the linear economy (take, make, sell, dispose) we seek to disrupt. Massive societal benefits also stem from such a model, including less waste, a lower carbon footprint, new employment opportunities and access to products and technologies for groups that couldn’t have afforded them before.

Supply chain resilience and critical raw materials

To create many components that make up electronic products, we need specific critical raw materials. Demand for these materials is growing across a range of industries — including not only telecommunications but also the renewable energy technologies necessary for a clean energy future.

“Critical raw materials are often mined and produced in only a handful of countries, which may make them prone to trade barriers, political instability and other socio-economic risks,” says James Souder, consultant at sustainability think tank, Metabolic. Read more